Views: 0 Author: Site Editor Publish Time: 2024-12-12 Origin: Site

When it comes to vehicle maintenance, wheel alignment is one of the most critical tasks that ensures both safety and performance. For automotive workshops, having the right wheel alignment clamp is essential to achieving accurate alignment and minimizing costly mistakes. Wheel alignment clamps secure the wheels in place while precise measurements are taken, allowing for proper adjustments to the camber, caster, and toe angles of a vehicle. The right clamp can make a significant difference in both the efficiency and accuracy of the alignment process.

Selecting the best wheel alignment clamp for your workshop is not always a straightforward decision. With so many options available in the market, it is crucial to consider various factors, including the type of vehicles being serviced, clamp material, clamp capacity, and compatibility with your alignment system. This comprehensive guide will help you understand these factors and make an informed decision.

Before you begin choosing a wheel alignment clamp, it’s essential to understand the different types available in the market. Each type of clamp is designed to suit particular alignment tasks and vehicle types. Broadly, the most common types of wheel alignment clamps are:

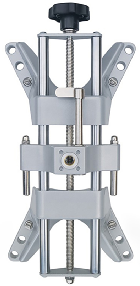

Rim clamps are the most widely used type in the industry. These clamps grip the edges of the wheel rims to ensure the wheel remains stationary during the alignment process. Rim clamps are ideal for vehicles with standard wheel designs and are easy to use in both passenger cars and light trucks. They are particularly helpful for aligning wheels with larger rims and wider tires.

Advantages of Rim Clamps:

Suitable for a wide range of vehicle types, including standard and large tires.

Provide a secure hold on the wheel rim, reducing the chance of error in measurement.

Easy to adjust for different rim sizes.

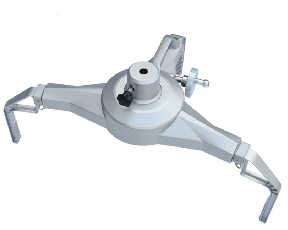

The tire clamp is a wheel clamp that mainly clamps the outer diameter of the tire to prevent scratching the wheel hub. It is also an accessory used to clamp the tire before doing a four-wheel alignment test.

Advantages of Tyre Clamps:

Provide a solid connection to the wheel hub for vehicles with hub-centric wheels.

More durable and long-lasting for specific high-performance applications.

Provide high precision for professional and specialized workshops.

Magnetic clamps use strong magnets to secure the alignment sensors to the wheel. These clamps are often used for high-precision alignment, where minimal interference is needed. Magnetic clamps are also great for aligning low-profile or unconventional tires.

Advantages of Magnetic Clamps:

Easy to attach and remove without damaging the wheel.

Provide quick alignment without the need for physical adjustments to the clamp.

Ideal for tire shops and workshops with frequent vehicle model changes.

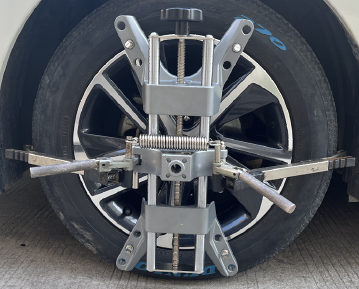

Wheel clamp with arms that can be used to hold the tire

By clamping the wheel hub and securing the tire, this product offers superior stability and protection against theft. Its universal fit and durable construction make it a reliable choice for anyone in need of vehicle security.

Advantages of Wheel Clamp with Arms:

The wheel clamp effectively clamps the wheel hub, providing a robust solution to prevent unauthorized movement of vehicles.

With arms designed to hold the tire firmly in place, the clamp ensures that the vehicle remains secure even in adverse conditions.

Made from high-quality materials, the wheel clamp is built to withstand harsh weather conditions and resist corrosion, ensuring long-lasting performance.

When choosing the best wheel alignment clamp for your workshop, several factors need to be considered. These include the type of vehicles you service, clamp material, clamp capacity, and the compatibility with your alignment system. Let’s take a closer look at each of these factors.

The type of vehicles you service plays a significant role in selecting the right wheel alignment clamp. Workshops that service a broad range of vehicles, from compact cars to large trucks, need a versatile clamp that can handle different tire sizes and wheel designs.

Passenger Cars and Light Vehicles: For most passenger cars and light trucks, rim clamps or center clamps are typically sufficient. These clamps can securely hold the wheels in place and provide reliable alignment results.

Heavy-Duty Vehicles (Trucks, SUVs, etc.): Workshops that regularly service large or heavy-duty vehicles require clamps with high load-bearing capacities and enhanced durability. Pneumatic or hydraulic clamps are often ideal for these applications due to their strong grip and ability to handle larger tires.

Specialized or High-Performance Vehicles: For specialized vehicles like sports cars, high-performance vehicles, or vehicles with unique wheel designs, center clamps or magnetic clamps may be the best choice. These clamps ensure high precision and minimal interference with the wheel design.

The material of the wheel alignment clamp is an essential factor in determining its durability and strength. Wheel alignment clamps are typically made from materials such as:

Steel: Steel is the most common material used for clamps. It is strong, durable, and resistant to wear and tear, making it suitable for high-volume workshops that service a wide variety of vehicles. Steel clamps are also more cost-effective compared to other materials.

Aluminum: Some high-end clamps are made from aluminum, which is lighter than steel but still strong enough to perform the task. Aluminum clamps are often used for high-precision applications and may be favored in specialized workshops for luxury vehicles.

Plastic or Composite Materials: In some cases, wheel alignment clamps are made from high-strength plastic or composite materials. These clamps are lighter, more cost-effective, and easier to handle, but they may not offer the same durability as metal clamps.

The clamp capacity refers to the maximum size of the wheel or tire that a particular clamp can secure. It is important to choose a clamp that can handle the wheel sizes and types you work with most often in your shop. For example:

If your workshop mainly deals with passenger vehicles, a clamp with a standard capacity (typically around 12 to 22 inches) should suffice.

For larger vehicles, such as SUVs and trucks, you will need a clamp that can accommodate larger wheel diameters, ranging up to 30 inches or more.

Choosing a clamp with adjustable capacity is often a good idea, as it allows you to handle various vehicle types without having to purchase multiple clamps.

While high-quality wheel alignment clamps may have a higher upfront cost, they can offer significant savings in the long run due to their durability and the accuracy they provide. A good clamp minimizes the risk of error during alignment, which can lead to costly mistakes and damage to vehicles. Invest in a clamp that offers the best balance between cost and quality based on the vehicles you service and the volume of work in your shop.

Choosing the right wheel alignment clamp for your workshop is crucial for maintaining accurate, efficient, and safe vehicle alignment. By considering factors such as the types of vehicles you service, the material and capacity of the clamp, compatibility with your alignment system, and durability, you can select a clamp that fits your needs and budget.

Whether you are a small garage working on passenger vehicles or a large workshop handling heavy-duty trucks, investing in the right wheel alignment clamp will ensure that your alignment tasks are completed with precision and that your customers receive the best service possible.